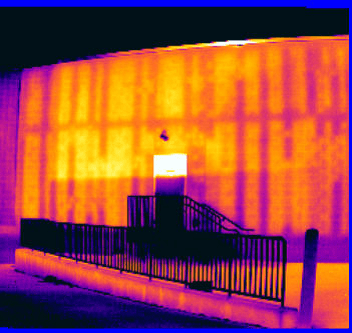

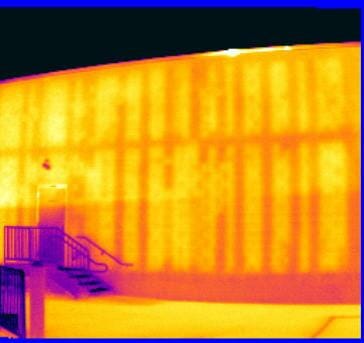

Block Wall Scan

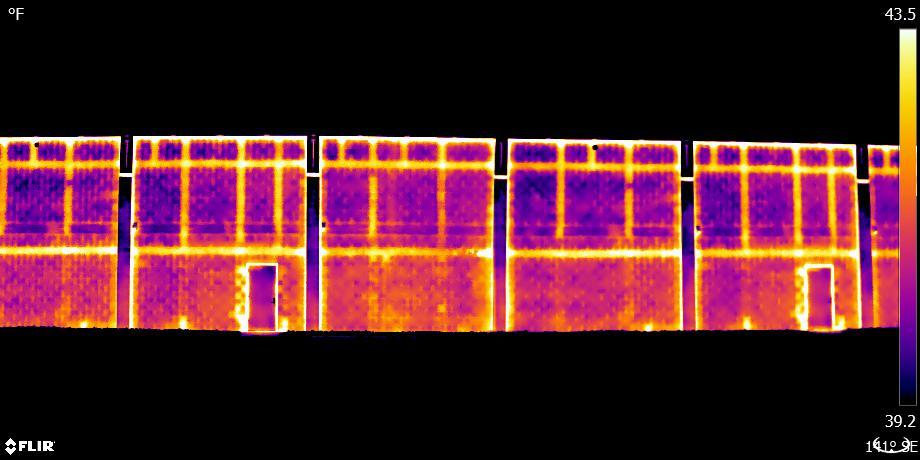

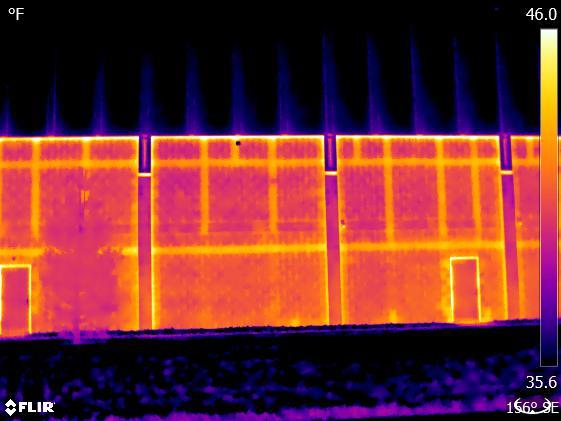

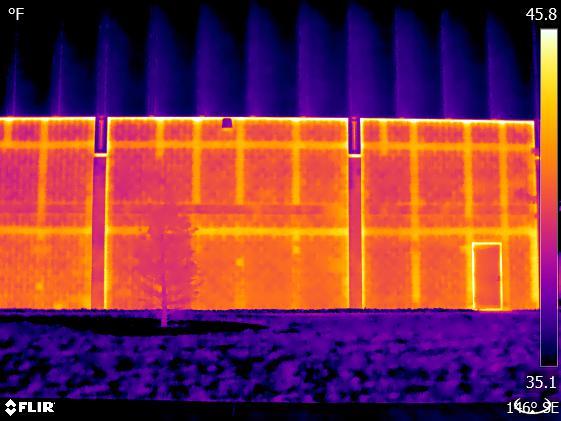

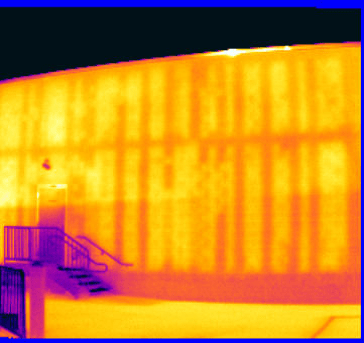

Block Wall Scan – Concrete Block walls (CMU) are a commonly used construction method – yet once a block wall is built, it can be almost impossible to visualize issues within the block wall. Thermography- Block Wall Scan IR is a non-destructive method to inspect CMU for proper grouting and insulation (including areas of missing grout and insulation) and to ensure proper location of structural components.

Block Wall Scan – Concrete Block walls (CMU) are a commonly used construction method – yet once a block wall is built, it can be almost impossible to visualize issues within the block wall. Thermography- Block Wall Scan IR is a non-destructive method to inspect CMU for proper grouting and insulation (including areas of missing grout and insulation) and to ensure proper location of structural components.

Block Wall Scan IR – Infrared Inspection method of concrete block walls is the unsurpassed way to visualize the structural integrity of the grouted cells or missing reinforcement in the entire Block wall section. Infrared testing can be performed at any time during the construction process without delaying or interrupting any other trades or affecting the progress of the building progress.

Infrared thermography can be utilized as a building quality assurance tool, as well as providing due diligence for real estate transactions. Almost all building materials will retain heat energy and therefore can be checked for quality of installation.

Improper installation of insulation and/or seals in buildings can be seen in the form of heat loss and air and water leaks. Also, building components “inside” the walls, ceilings and floors are recognizable because of their differences in mass.

For example, infrared thermography can be used to determine the presence and correct placement of grouted cells in concrete block walls. If the owner of a new block building spends a little money checking their (the low-bidder’s) work with infrared thermography, the contractor will be forced to build the building per specifications or face the added direct cost of repairs and resulting loss of schedule repercussions and not to mention law suit.

What are the Benefits of the Block Wall Scan IR?

- A block wall scan is non-destructive

- You have a documented, thermographic record of the structural components and cells

- If discrepancies are noted, the areas needing repair are easy to pinpoint and corrected with surgical precision. An additional scan can confirm these repairs

- A block wall scan reduces the liability of all parties to the process. If the wall or structural elements fail (act of god, impact, etc.), a forensic examination of the damage may reveal issues that could have been avoided by an infrared scan

- The masonry contractor, general contractor, professional engineer, architect, building owner and developer will be held accountable

- Most projects use the lowest bidder. An infrared block wall scan is a sensible investment to insure that your low bidder is performing the work as specified. If the low bidder knows the wall is to be scanned, they will have to build to the specifications or face the cost of repair, loss and legal ramifications

Why Schedule an Infrared (IR) Block Wall Scan Inspection with Us?

In the past construction professionals thought the only way that one can know whether quality work of the grouted cells, insulation and, other crucial components of the block wall are properly placed is to open it up with destructive or invasive methods, where the grout or insulation is supposed to be and see if it is there.

However, this method of testing is destructive and time consuming as the small holes do not show where there may be blockages and/or if too much grout exists. Which means you could have massive structural integrity issues only a few feet away from the hole! The most popular way to make sure that grouting and rebar in place is to require the builders to install an inspections port, cut into the block faces. This is a very costly, time-consuming and sloppy methods.

Concrete block walls are not structurally sound without proper rebar and grouting. Grouting is concrete that is pumped into the center of the blocks; this ties the blocks, the rebar, and the entire wall system together. Without proper grouting, concrete walls are dangerous.

If voids are present in the grouted cells, they can reduce the structural capacity of the systems and, in the case of reinforced masonry, can limit the effectiveness of the steel reinforcement. These voids often collect water, leading to interior damage and corrosion of the reinforcement. Today, a block wall scan utilizing infrared technology is the best tool for the surveying of a masonry wall to find deficiencies in the structural components. It’s fast, inexpensive, and extremely accurate.